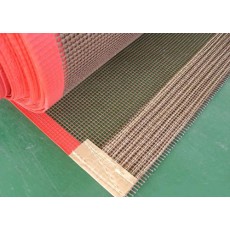

Teflon seam fusing machine belt

- ← Pizza belt Dryer belt PTFE teflon fiberglass conveyor belt with kevla border

- Jiangsu Ruida PTFE seamless sealing belt →

Product Description

Ruida produced Ptfe fusing seamless belt, ptfe seamless fusing belt, harshima&oshima belt,teflon seamless belt. Welcome you purchase our standard products or send us your OEM requests.

Product Details

|

Place of Origin: Jiangsu, China (Mainland) |

Brand Name: Ruida PTFE fiberglass fabric, sealing machine belt |

Model Number: RD9013- RD9045 |

|

|

Weight: 260-820 |

Width: 1250-3500mm |

|

Alkali Content: Alkali Free |

Weave Type: Plain Woven |

Yarn Type: E-Glass |

|

Standing Temperature: -140~260℃ |

|

|

Specifications

seamless sealing belt

1.Manufacturer,stocked.

2, Super non-sticky character, high temperature resistance.

3.FDA/SGS/REACH

Jiangsu Ruida supply several belt types

1. PTFE seamless fusing machine belt:

the belt is made of high tensile fiberglass or Kevlar, knitted by special equipment and coated with fine PTFE. Seamless belt overcomes former problems of traditional joint fusing machine belt such as bad stability, ruptures, and deflecting for different girth on two sides at the joint. The using life of seamless PTFE Fusing Machine Belt are much longer than all kinds of joint PTFE Fusing Machine Belt.

2.2ply fusing machine belt:

with static-resistance varnished cloth inside and tearing-resistance fiberglass cloth outside, 2ply belt has a great improvement on its intensity, long using life, well balanced thickness, excellent deflecting preventing capacity, smooth surface, it’s better for super thin fabric fusing.

3.Common seam fusing machine belt:

Seam fusing machine belt is made of fine material. The surface is smooth and luster and the price is competitive. It can substitute imported high price belts.

PTFE Belting

Ruida manufactures various of belts with its material of smooth ptfe fabric,ptfe mesh, kevla, silicon rubber etc to custom specifications, depending on each customer’s individual needs. To help determine the best belt for your unique application, you need provide the following information for our experienced technical manager to discuss your requirement.

Ordering Your Ruida Belt

Whenever possible, have the following information available:

* Dimensions of belt: width and length

* Desired splice, edge reinforcement and tracking devices, where needed

* Pulley size and type

* Any special construction or instructions concerning the fabrication of your Ruida belt. In some cases of

complex fabrication,a print may be requested.

Choosing the Right Material

There are a number of factors to keep in mind when choosing the belting material for your application:

* Temperature Range – Our ptfe fabrics have the capabilities of withstanding -70°C- +260°C constant operating temperatures.

* Pliability – If the material is to track around pulleys that drive the belt, the diameter of the pulley is critical. The smaller the roller the more flexible the belt must be. Ruida’s thinner materials (0.010” and under) are more pliant than the heavier coated fabrics.

* Release Qualities – The surface finishes of our materials range from a rough, semi-porous finish to a super smooth surface. The release or fabric impression results desired will be a determining factor.

* Strength – Options to be considered are breaking, tensile and tear strength. How much of a load the belt carries, how fast it moves and how tightly it will be tensioned all must be considered.

Fabric Grades

Learn more about the various fabric grades available when constructing your belt.

Applications

Learn about the different applications for ptfe coated fiberglass ,silicon coated glass tapes, fabrics and belts.

Fabrication Options

Learn more about the many options available for constructing your Ruida conveyor belt.

|

Metallic Splices |

|

|

|

Alligator Splice

|

|

|

Clipper Splice

|

|

Non-Metallic Splices |

|

|

|

Peek Splice

|

|

|

Smartloop Splice

|

|

|

Fabric Notch Splice

|

|

Endless Splices |

|

|

|

Butt Splice

|

|

|

Overlap Splice

|

|

|

Scarfed Splice

|

Edge Reinforcements

RUIDA belts can be supplied with strips of heat-sealed film or fabric on one or both edges of your belt. This reinforcement serves a dual purpose; it reduces fraying of belt edges which rub on guiding rollers and it also provides the strongest possible anchor for guiding pins, snaps and grommets.

|

|

TFE-Film Edge, Heat-Sealed surface. The TFE film is available in 3 mil, black or clear, or 10 mil tan (1" surface only). |

|

|

Fabric Edge, Heat-Sealed

|

|

|

Fabric Edge, Sewn & Sealed

|

Two-Ply Belts

Two-ply belts are constructed of two plies of TFE-GLASS™, laminated together with staggered splices. This provides a smooth, continuous thickness along the entire belt length which guarantees a uniform seal in packaging and heat-sealing applications. The belts are typically available in widths of ½" – 3".