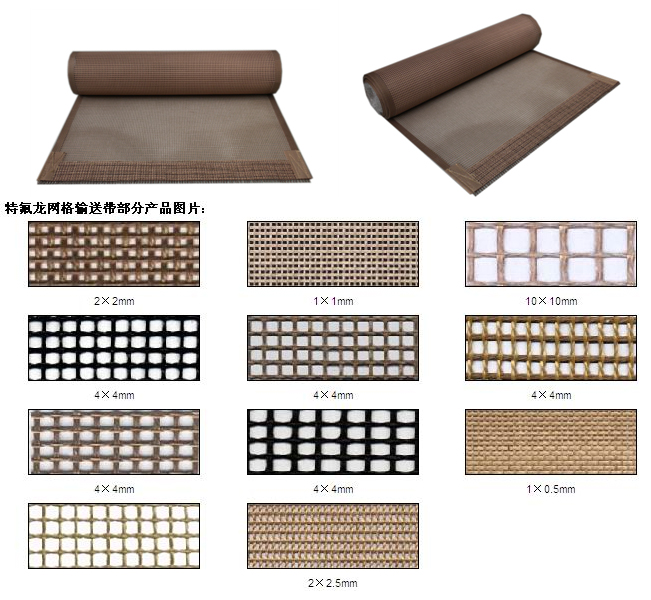

RUIDA PTFE coated kevlar mesh conveyor belt

- ← Teflon coated fiberglass mesh conveyor belt,teflon mesh,BBQ grill mat

- PTFE coated kevlar fabric belts industrial belt →

Product Description

Ruida produced PTFE fabric belt, ptfe conveyor belt, teflon conveyor belt, dryer belt,food conveyor belt. Welcome you purchase our standard products or send us your OEM requests.

Product Details

Quick Details

Condition: New

Type: mesh belt

Material: Kevlar

Material Feature: Heat Resistant

Structure: Belt Conveyor

Load Capacity: depends

Place of Origin: China (Mainland)

Brand Name: RUIDA

Model Number: RDKV

Color: yellow, black

Product Type: Aramid Fabric

Technics: Woven

Use: Industry, Military,

Chemical, Petroleum

Pattern: Coated

Style: Plain

Type: Kevlar Fabric

Packaging & Delivery

Packaging Details: bubble paper, carton, palletDelivery Detail: 7-15days

Specifications

kevlar mesh conveyor belt:

1. military; 100%kevlar/aramid

2. color:yellow

3. width: 4000mm

Features:

This product has good flame retardant, resistance to abrasion, the cutting performance. Widely used in safety protection, outdoor supplies and fire fighting field

Appilication:

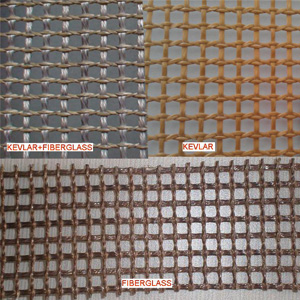

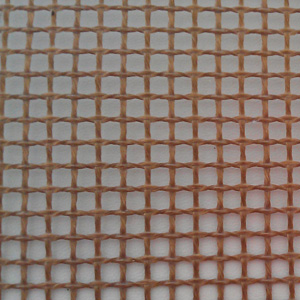

1.KEVLAR can provide a variety of different formative change, its unique characteristics, high temperature resistant, high tensile, high grinding degree (hardness) and low elongation, impact resistance and resistance to chemical and high performance, from the original wire and twist yarn (Ripcord), weaving (plain weave/knitting), plus resin (coating) or and other material composite (composite) can provide different functions.

2.KEVLAR also have excellent heat resistance performance, can not only in the negative to the positive 196 degrees 204 degrees temperature range continuous use but there is no obvious change or detract from; At the same time also has the insoluble, fire resistance (not combustion), will only in 427 degrees began to the characteristics of the carbide, even in negative 196 degree low temperatures, also does not change CuiHe performance loss phenomenon, and can endure temperature as high as 538 degrees short time contact with excellent heat resistance performance.

3.KEVLAR can also use reinforcement many now commercialized high polymer materials, and glass fiber reinforcement materials as easy processing, the use of KEVLAR reinforcing than using glass fibre light 30% to 35%, and 2.5 times as strong rigidity, and KEVLAR and carbon fiber common reinforcement of composite materials also have excellent compression strength.

KEVLAR grey fabric has high strength flame retardant, high temperature resistant, put cut, tear resistance, use and a variety of civil defence and industrial fields.

PTFE Belting

Ruida manufactures various of belts with its material of smooth ptfe fabric,ptfe mesh, kevla, silicon rubber etc to custom specifications, depending on each customer’s individual needs. To help determine the best belt for your unique application, you need provide the following information for our experienced technical manager to discuss your requirement.

Ordering Your Ruida Belt

Whenever possible, have the following information available:

* Dimensions of belt: width and length

* Desired splice, edge reinforcement and tracking devices, where needed

* Pulley size and type

* Any special construction or instructions concerning the fabrication of your Ruida belt. In some cases of

complex fabrication,a print may be requested.

Choosing the Right Material

There are a number of factors to keep in mind when choosing the belting material for your application:

* Temperature Range – Our ptfe fabrics have the capabilities of withstanding -70°C- +260°C constant operating temperatures.

* Pliability – If the material is to track around pulleys that drive the belt, the diameter of the pulley is critical. The smaller the roller the more flexible the belt must be. Ruida’s thinner materials (0.010” and under) are more pliant than the heavier coated fabrics.

* Release Qualities – The surface finishes of our materials range from a rough, semi-porous finish to a super smooth surface. The release or fabric impression results desired will be a determining factor.

* Strength – Options to be considered are breaking, tensile and tear strength. How much of a load the belt carries, how fast it moves and how tightly it will be tensioned all must be considered.

Fabric Grades

Learn more about the various fabric grades available when constructing your belt.

Applications

Learn about the different applications for ptfe coated fiberglass ,silicon coated glass tapes, fabrics and belts.

Fabrication Options

Learn more about the many options available for constructing your Ruida conveyor belt.

|

Metallic Splices |

|

|

|

Alligator Splice

|

|

|

Clipper Splice

|

|

Non-Metallic Splices |

|

|

|

Peek Splice

|

|

|

Smartloop Splice

|

|

|

Fabric Notch Splice

|

|

Endless Splices |

|

|

|

Butt Splice

|

|

|

Overlap Splice

|

|

|

Scarfed Splice

|

Edge Reinforcements

Taconic belts can be supplied with strips of heat-sealed film or fabric on one or both edges of your belt. This reinforcement serves a dual purpose; it reduces fraying of belt edges which rub on guiding rollers and it also provides the strongest possible anchor for guiding pins, snaps and grommets.

|

|

TFE-Film Edge, Heat-Sealed surface. The TFE film is available in 3 mil, black or clear, or 10 mil tan (1" surface only). |

|

|

Fabric Edge, Heat-Sealed

|

|

|

Fabric Edge, Sewn & Sealed

|

Two-Ply Belts

Two-ply belts are constructed of two plies of TFE-GLASS™, laminated together with staggered splices. This provides a smooth, continuous thickness along the entire belt length which guarantees a uniform seal in packaging and heat-sealing applications. The belts are typically available in widths of ½" – 3".

|

|