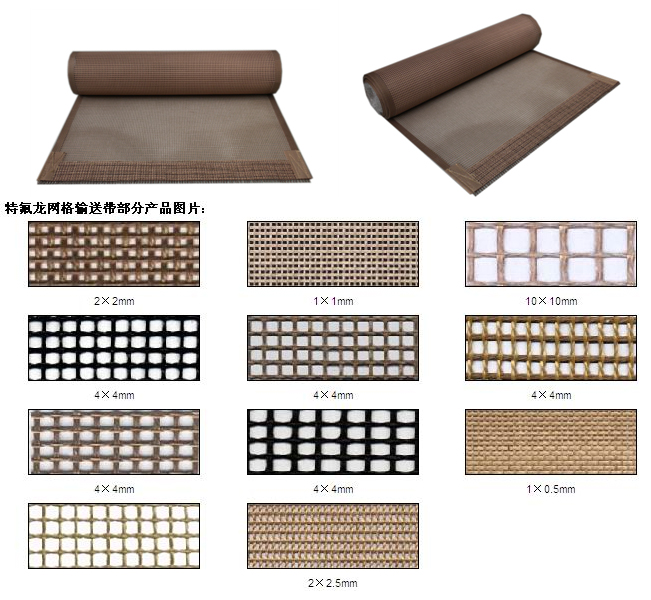

ptfe mesh fabric cloth conveyor belt

|

Place of Origin: Jiangsu, China (Mainland) |

Brand Name: Ruida fiberglass fabric |

Model Number: RD6001-RD6015 |

|

|

Weight: 400-600G |

Width: 4M |

|

Mesh Size: 1*1;1*0.5;2*2.5;4*4;10*10 |

Weave Type: Plain Woven |

Yarn Type: E-Glass |

|

Alkali Content: Alkali Free |

Standing Temperature: -70-260℃ |

|

Conveyor Belt Styles and Specifications:

|

Item |

Mesh Size |

material |

Thickness |

Weight |

Temperature resistance |

Max Width |

Tensile Strength |

|

RD6001 |

1x1mm |

fiberglass |

0.5mm |

370g/m² |

-70-260°C |

4000mm |

310/290N/cm |

|

RD6002 |

2x2mm |

fiberglass |

0.7mm |

450g/m² |

-70-260°C |

4000mm |

350/310N/cm |

|

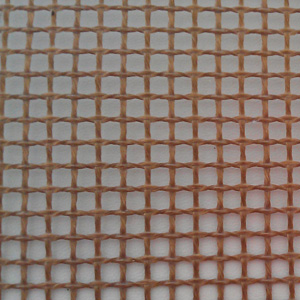

RD6003 |

4x4mm |

fiberglass |

1.0mm |

400g/m² |

-70-260°C |

4000mm |

390/320N/cm |

|

RD6004 |

4x4mm |

fiberglass |

1.0mm |

450g/m² |

-70-260°C |

4000mm |

390/320N/cm |

|

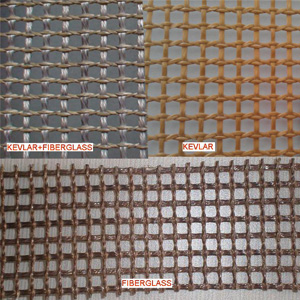

RD6007 |

4x4mm |

Kevlar + fiberglass |

1.2mm |

600g/m² |

-70-260°C |

4000mm |

895/370N/cm |

|

RD6008 |

4x4mm |

fiberglass |

1.2mm |

580g/m² |

-70-260°C |

4000mm |

560/360N/cm |

|

RD6010 |

4x4mm |

Kevlar |

1.0mm |

500g/m² |

-70-260°C |

4000mm |

900/600N/cm |

|

RD6012 |

4x4mm |

fiberglass |

1.0mm |

550g/m² |

-70-260°C |

4000mm |

395/370N/cm |

|

RD6013 |

10x10mm |

fiberglass |

1.0mm |

450g/m² |

-70-260°C |

4000mm |

360/300N/cm |

|

RD6014 |

0.5x1mm |

fiberglass |

0.5mm |

420g/m² |

-70-260°C |

4000mm |

310/290N/cm |

|

RD6015 |

2x2.5mm |

fiberglass |

0.9mm |

600g/m² |

-70-260°C |

4000mm |

390/320N/cm |

Conveyor Belt select fine glassfiber or Kevlar as basic weaving material, coated with excellent PTFE resin to

make it into various PTFE open mesh conveyor belts

Conveyor Belt Applications:

1. Drying machine for non-woven textile, textile printing, silk-prnting and dyeing machine.

2. Shrinking machine for garment fabric, high-frequency and UV dryer.

3. Conveyer belt for hot-air dryer, various of food baking, quick-frozen machines.

4. Oiling machine for paper glazing and waxing, plant engineering.

5. Seperating sheet for hardboard production etc.

PTFE Belting

Ruida manufactures various of belts with its material of smooth ptfe fabric,ptfe mesh, kevla, silicon rubber etc to custom specifications, depending on each customer’s individual needs. To help determine the best belt for your unique application, you need provide the following information for our experienced technical manager to discuss your requirement.

Ordering Your Ruida Belt

Whenever possible, have the following information available:

* Dimensions of belt: width and length

* Desired splice, edge reinforcement and tracking devices, where needed

* Pulley size and type

* Any special construction or instructions concerning the fabrication of your Ruida belt. In some cases of

complex fabrication,a print may be requested.

Choosing the Right Material

There are a number of factors to keep in mind when choosing the belting material for your application:

* Temperature Range – Our ptfe fabrics have the capabilities of withstanding -70°C- +260°C constant operating temperatures.

* Pliability – If the material is to track around pulleys that drive the belt, the diameter of the pulley is critical. The smaller the roller the more flexible the belt must be. Ruida’s thinner materials (0.010” and under) are more pliant than the heavier coated fabrics.

* Release Qualities – The surface finishes of our materials range from a rough, semi-porous finish to a super smooth surface. The release or fabric impression results desired will be a determining factor.

* Strength – Options to be considered are breaking, tensile and tear strength. How much of a load the belt carries, how fast it moves and how tightly it will be tensioned all must be considered.

Fabric Grades

Learn more about the various fabric grades available when constructing your belt.

Applications

Learn about the different applications for ptfe coated fiberglass ,silicon coated glass tapes, fabrics and belts.

Fabrication Options

Learn more about the many options available for constructing your Ruida conveyor belt.

|

Metallic Splices |

|

|

|

Alligator Splice

|

|

|

Clipper Splice

|

|

Non-Metallic Splices |

|

|

|

Peek Splice

|

|

|

Smartloop Splice

|

|

|

Fabric Notch Splice

|

|

Endless Splices |

|

|

|

Butt Splice

|

|

|

Overlap Splice

|

|

|

Scarfed Splice

|

Edge Reinforcements

Taconic belts can be supplied with strips of heat-sealed film or fabric on one or both edges of your belt. This reinforcement serves a dual purpose; it reduces fraying of belt edges which rub on guiding rollers and it also provides the strongest possible anchor for guiding pins, snaps and grommets.

|

|

TFE-Film Edge, Heat-Sealed surface. The TFE film is available in 3 mil, black or clear, or 10 mil tan (1" surface only). |

|

|

Fabric Edge, Heat-Sealed

|

|

|

Fabric Edge, Sewn & Sealed

|

Two-Ply Belts

Two-ply belts are constructed of two plies of TFE-GLASS™, laminated together with staggered splices. This provides a smooth, continuous thickness along the entire belt length which guarantees a uniform seal in packaging and heat-sealing applications. The belts are typically available in widths of ½" – 3".

|

|