ruida high quality heat resistant teflon coated fiberglass fabric

Quick Details

|

Place of Origin: Jiangsu, China (Mainland) |

Brand Name: Ruida fiberglass fabric |

Model Number: RD9008-RD9100 |

|

Application: Fiberglass Mesh Cloth |

Weight: 165-1650G/SQM |

Surface Treatment: PTFE Coated |

|

Width: 3-4M |

Weave Type: Plain Woven |

Yarn Type: E-Glass |

|

Alkali Content: Alkali Free |

Standing Temperature: 70°C to +260°C |

|

Packaging & Delivery

Packaging Details: fiberglass fabric is packed in plastic bag, carton, pallet

Delivery Detail: 3-10 days to deliver PTFE coated fiberglass cloth

Specifications

1.IFAI member

2.SGS Certified

3.PICC warranty.

4.Dupont&Daikin authority

VK Architectural membranes are manufactured with our own uniqe proprietary technology,of coating speciality woven B glass fabrics with PTFE resins.

PTFE coated glass fabrics could have higher structural strength than steel,(in certain conditions),and are unaffected by temperature variations between -80 to 260oC.Meanwhile PTFE coated Membranes'unique properties are water repellant,resistant to adverse weather conditions and almost totally self-cleaning. For this reasaon, VK Architectural membranes are excellent construction materials that provides superior properties, longer guaranteed life and enhanced asethetics.

ptfe/teflon fiberglass fabric

fiberglass fabric use best imported Fiberglass yarn as the weaving material to plain knit or specially knit into superior fiberglass basic cloth, coat it with fine PTFE(Teflon) resin then make it into various PTFE(Teflon) fabric in different thickness and widths.

Ruida PTFE Fabric Characteristic:

Generally, PTFE coated fiberglass fabric exhibits the following high-performance characteristics:

Non-stick surface

Excellent temperature resistance: from -100°F - +500°F (-73°C - +260°C)

Chemically inert

High tensile strength

Ruida PTFE Fabric Application:

Designed for a wide range of applications,Ruida PTFE fabric is available in several grades to match specific performance requirements.

Ruida Premium-A+ Grad ptfe Fabric

Featuring an extra heavy coating of PTFE, Ruida Premium- A Grade Fabric delivers a super-smooth surface, perfect for advanced applications, including:

Release sheets for cooking and baking applications

Laminate separator sheets

Specialized heat-sealing

Demanding, non-stick applications

Ruida Standard-A Grade PTFE Fabric

With a smooth surface and superb non-stick properties, Ruida Standard-A Grade Fabric serves the widest range of applications, including:

Release sheets on heat-sealing machines and laminate presses

Non-stick surfaces for paints, adhesives and food products

Gaskets, seals and bearings for chemicals, oils and gases

Thermal insulation for high-temperature and chemical-resistant applications

Covers for hot plates, platens, chutes, hoppers, troughs and rolls

Ruida Mechanical-B+ Grade PTFE Fabric

Designed to deliver resistance to high temperatures and chemicals, Ruida Mechanical-B Grade Fabric utilizes a medium coating of PTFE. Typical applications include chemical-resistant laboratory aprons and protective curtains, such as:

Bottle washers and paint spraying curtains

Food packaging

Acid protection

Ruida Economy-B Grade PTFE Fabrics

Providing a light coat of PTFE, Taconic Economy-Grade Fabrics are designed for large volume applications which require cost-efficiency, yet still need high performance. Typical uses include:

Leaders for processing paper, plastics, metallic foils and cloth

Separator sheets for processing uncured rubber

The manufacture of abrasive wheels

Ruida Porous Bleeder & Filter PTFE Fabrics

These fabrics are available over a wide range of porosity. Principle applications include:

filtration

strainers

pollution abatement

Ruida Crease & Tear Resistant PTFE Fabric

Provides an unusually flexible material for use in applications where high tear-strength and good flex-life are demanded.

Ruida Anti-static PTFE Fabrics

Ruida black Anti-static PTFE fabrics is provided with a carbon loading giving semi-conductive and anti-static properties to the material. It eliminates or reduces static problems in belt and slip sheet applications.

Advantages

1.High mechanical strength and dimensional stability;

2.Excellent translucent performance;

3.Suitable for specific acoustic filtration;

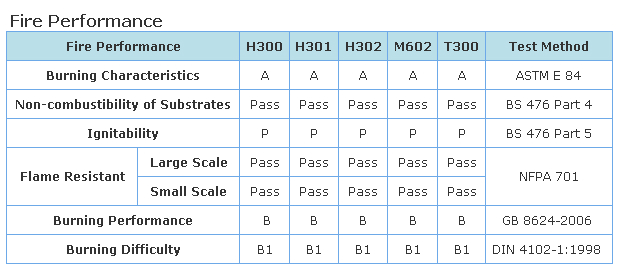

4,Superior fireproof properties and performance;

5.Great adaptability as a sound insulator;

6.Excellent independent self-cleaning performance;

warranty:

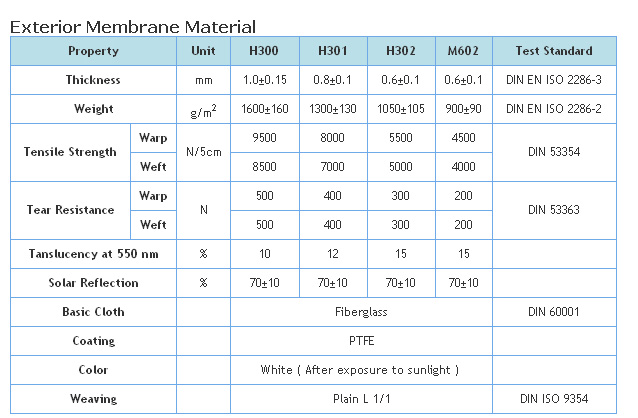

Specification details:

|

Part Number |

Overall Thickness (inches) |

Coated Weight (lbs/yd2) |

Tensile Strength Warp/Fill (lbs/in) |

TearStrength Warp/Fill (lbs) |

Max.Width(mm) | ||

| Premium Grade | |||||||

| 9039 | 0.0029 | 0.27 | 95/55 | 1.5/0.9 | 3200 | ||

| 9012 | 0.0049 | 0.49 | 150/130 | 2.5/2.0 | 1250 | ||

| 9015 | 0.006 | 0.6 | 150/115 | 2.1/1.8 | 1250 | ||

| 9025 | 0.0099 | 1.01 | 325/235 | 7.5/4.0 | 2800 | ||

| 9028AP | 0.011 | 1.08 | 320/230 | 5.4/3.6 | 2800 | ||

| 9045 | 0.0148 | 1.45 | 350/210 | 5.6/5.1 | 3200 | ||

| Standard Grade | |||||||

| 9007AJ | 0.0028 | 0.25 | 90/50 | 1.7/0.9 | 1250 | ||

| 9010AJ | 0.004 | 0.37 | 140/65 | 2.6/0.7 | 1250 | ||

| 9011AJ | 0.0046 | 0.46 | 145/125 | 3.0/2.2 | 1250 | ||

| 9014 | 0.0055 | 0.54 | 150/140 | 2.0/1.5 | 1250 | ||

| 9023AJ | 0.0092 | 0.94 | 250/155 | 4.9/3.0 | 2800 | ||

| 9035 | 0.0139 | 1.36 | 440/250 | 7.0/6.0 | 3200 | ||

| 9065 | 0.0259 | 1.76 | 420/510 | 15.0/8.0 | 4000 | ||

| Mechanical Grade | |||||||

| 9007A | 0.0026 | 0.2 | 80/65 | 2.3/1.0 | 1250 | ||

| 9010A | 0.004 | 0.37 | 145/135 | 2.3/1.6 | 1250 | ||

| 9021 | 0.0083 | 0.8 | 275/190 | 8.0/3.0 | 1250 | ||

| 9030 | 0.0119 | 1.14 | 375/315 | 7.0/6.0 | 2800 | ||

| Economy Grade | |||||||

| 9007 | 0.0026 | 0.17 | 70/60 | 2.9/0.8 | 1250 | ||

| 9010 | 0.004 | 0.36 | 135/115 | 3.0/2.7 | 1250 | ||

| 9023 | 0.0092 | 0.72 | 225/190 | 4.4/3.2 | 2800 | ||

| 9018 | 0.0074 | 0.7 | 270/200 | 8.0/4.0 | 1250 | ||

| 9028 | 0.0112 | 0.98 | 350/300 | 15.0/11.0 | 3200 | ||

| 9056 | 0.0222 | 1.34 | 320/250 | 50.0/40.0 | 4000 | ||

| 9090 | 0.0357 | 2.04 | 540/320 | 10.8/23.0 | 4000 | ||

| Porous Bleeder & Filter | |||||||

| 9006 | 0.0025 | 0.12 | 40/30 | 5.3/4.0 | 1250 | ||

| 9034 | 0.0135 | 0.77 | 175/155 | 21.0/12.0 | 3200 | ||

| Crease & Tear Resistant | |||||||

| 9008 | 0.0032 | 0.31 | 90/50 | 1.6/0.5 | 1250 | ||

| 9011 | 0.0046 | 0.46 | 125/130 | 4.1/3.7 | 1250 | ||

| 9014 | 0.0056 | 0.52 | 160/130 | 5.0/3.0 | 1250 | ||

| 9066 | 0.0261 | 1.8 | 450/430 | 50.0/90.0 | 4000 | ||

| TAC-BLACK™ (Available anti-static) | |||||||

| 9013 | 0.0048 | 0.45 | 170/140 | 2.2/1.8 | 1250 | ||

| 9014 | 0.0057 | 0.55 | 150/120 | 1.7/1.4 | 1250 | ||

| 9024 | 0.0095 | 0.92 | 230/190 | 4.0/3.0 | 2800 | ||

| 9024AS | 0.0095 | 0.92 | 230/190 | 4.0/3.0 | 2800 | ||

| 9037AS | 0.0146 | 1.39 | 405/270 | 8.5/7.2 | 3500 | ||